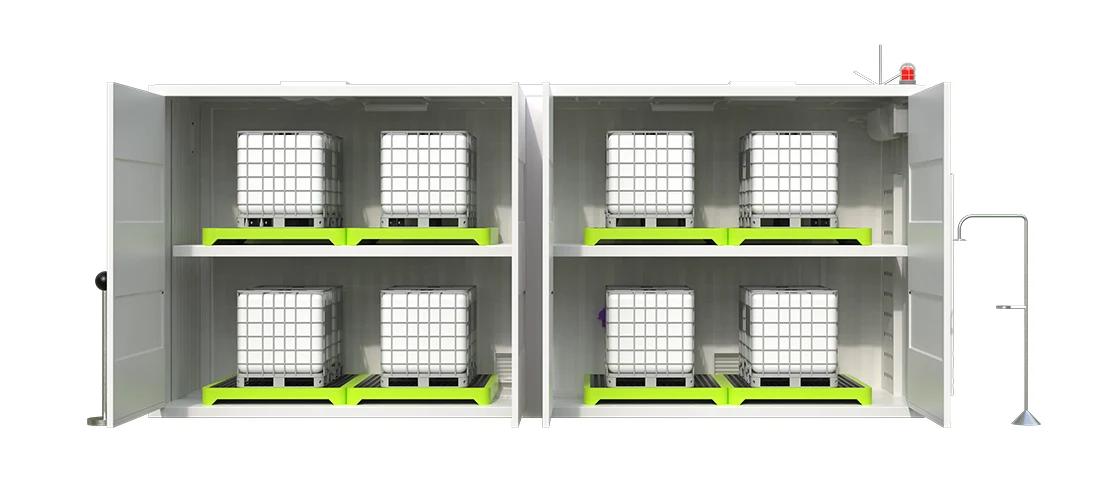

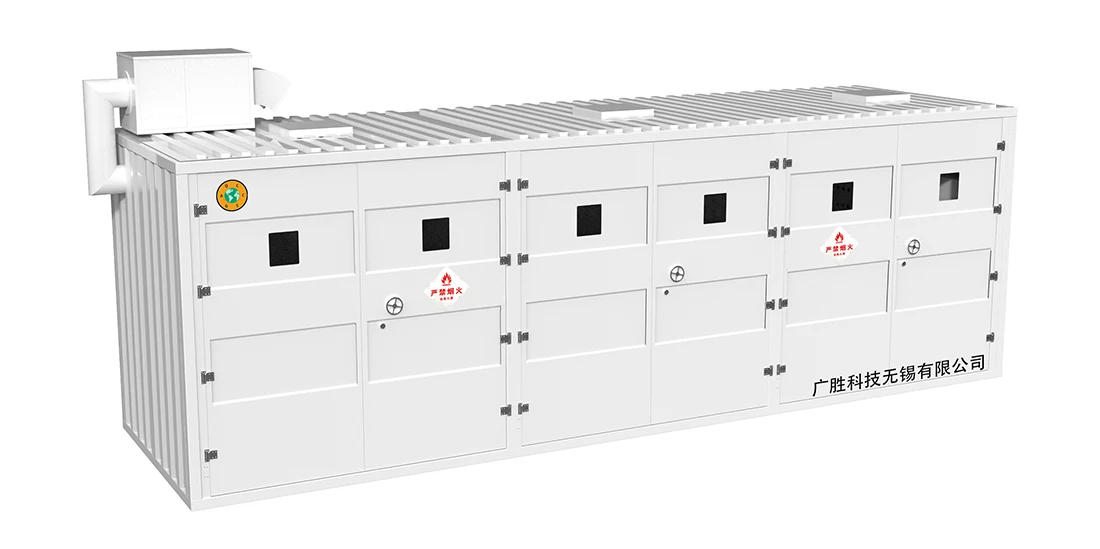

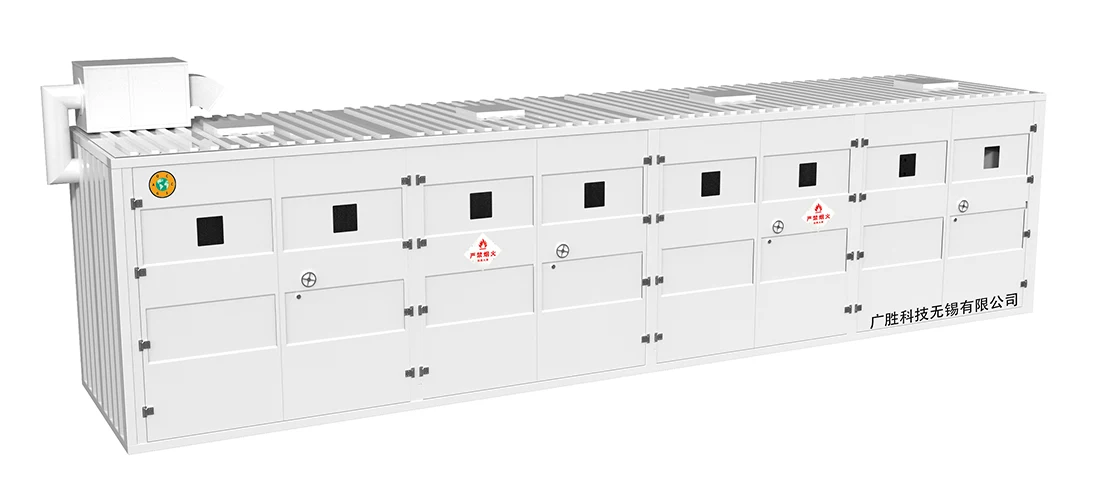

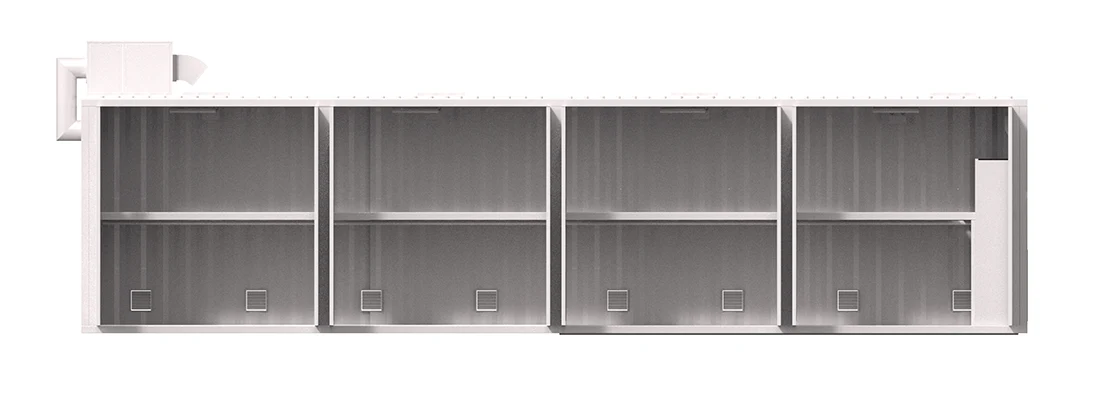

The layered outdoor storage cabinet is specifically designed to meet the stringent requirements of outdoor storage. It offers several size options: 2800 mm in height, 3000 mm in width, and 4000 mm in depth; 2800 mm in height, 3000 mm in width, and 6000 mm in depth; 2800 mm in height, 3000 mm in width, and 9000 mm in depth; 2800 mm in height, 3000 mm in width, and 12000 mm in depth. The interior of the cabinet provides a spacious area, suitable for storing various items, including hazardous waste, solid waste, and flammable, explosive, and dangerous chemicals. The cabinet features a sturdy double - layer structure. The outer layer, made of corrugated boards, is durable and can withstand harsh weather conditions. The inner layer is filled with 80 - mm thick fire - resistant and heat - insulating materials, ensuring excellent thermal insulation and fire protection performance.

This storage cabinet is equipped with a comprehensive set of safety and environmental control facilities, making it a reliable choice. It has a fire - and - theft - proof system, waterproof protection device, and explosion - proof electrical equipment. The integrated fire - fighting system, including a piped heptafluoropropane fire extinguishing device, can quickly and effectively suppress fires. In addition, the advanced environmental monitoring system continuously monitors the concentration of volatile organic compounds (VOCs), temperature, humidity, and ventilation, ensuring a safe and stable storage environment. Whether for industrial, commercial, or public institutional use, this layered outdoor storage cabinet provides a safe and convenient solution for outdoor storage needs.

|

Serial Number |

tructure Name |

Function, Parameter Description and Configuration |

|

1 |

Cabinet |

The cabinet frame is mainly made of corten A 2.0mm steel plate. The outer cabinet consists of a steel frame, vertical corrugated side panels and end faces, as well as a top plate with horizontal and vertical corrugations, all of which are pressed from cold-rolled steel plates. The entire exterior of the cabinet is sprayed with anti-rust paint, the inner wall is coated with anti-corrosion paint, and the bottom is sprayed with polytetrafluoroethylene, enabling the whole cabinet to have anti-corrosion capabilities. The inner wall of the cabinet uses Class A fireproof and heat-insulating materials, and the thickness of the heat-insulating layer is ≥80mm. In case of an explosion, the top of the cabinet is equipped with an explosion venting panel. There are 2 explosion venting openings, each with a size of 1.1*1.1m, and the explosion venting area is ≥0.11m²/m³. The explosion venting surface is designed according to the BGV B4 standard. The cover of the explosion venting panel is loosely installed and equipped with a fixed chain, which will automatically fall back after the explosion venting is completed. The explosion venting panel has a snow shed to prevent rain and snow, and the explosion venting pressure is 580 Mpa. The cabinet door is made of single or composite materials with functions such as fire prevention, lightning protection, anti-static, anti-corrosion, and non-sparking. It is equipped with a built-in fire push rod lock. When the door is opened by the push rod, it will trigger an alarm sound of 100 decibels and linkage alarm. The door opens in the direction of evacuation and can be opened from the inside.1.6 The interior of the cabinet is divided into areas, and an operation room is set up for operators to make protective preparations before entering the storage area. |

|

2 |

Intelligent Control System |

2.1 The control system is equipped with a 7-inch full-color screen, which can display the status of various parameters in real time.2.2 The entire device is centrally controlled by a microcomputer system. According to the parameters set by the customer, the system automatically and real-timely detects the parameters of various sensors, as well as functions such as access control, lighting, early warning and alarm, and temperature control.2.3 In case of potential danger, the system will activate the audible and visual alarm, and the alarm sound is above 85 decibels, providing long-distance early warning. |

|

3 |

Ventilation and Exhaust System |

The ventilation and exhaust system is composed of 4 ventilation louvers and ventilation pipe manifolds. Ventilation louvers are installed inside the cabinet, and an anti-insect and anti-rat net is installed inside the louvers for air intake. |

|

4 |

Exhaust Gas Purification System |

4.1 It is composed of 1 plasma purifier, connecting pipe manifolds, etc.4.2 It is independent of the cabinet and connected to the cabinet through pipelines, which is convenient for maintenance and helps to reduce noise, vibration and harm to personnel during operation.4.3 The exhaust gas emissions after purification treatment comply with the "GB16297 Comprehensive Emission Standard of Atmospheric Pollutants".4.4 Requirements for the plasma purifier: Treatment air volume is 5000 M³/h, and energy consumption is 400 W. |

|

5 |

Temperature Control System |

It is composed of a full inner wall fireproof and heat-insulating layer and 1 explosion-proof air conditioner. 5.1 A 50mm-thick Class A fireproof and heat-insulating layer is installed on the inner wall of the cabinet to prevent the internal temperature from getting too high when exposed to sunlight.5.2 There is an explosion-proof air conditioner inside the cabinet, which can effectively reduce the temperature inside the cabinet when the room temperature is too high.5.3 Requirements for the explosion-proof split air conditioner (window air conditioners are strictly prohibited, and anti-vibration and anti-noise measures are required): Rated voltage is 220V 50Hz, rated current for cooling/heating is 10.7/16.5A, waterproof grade is IP*4, and noise level (indoor/outdoor) is 40/59 dB. |

|

6 |

Explosion - proof Power Supply System |

It is composed of 1 explosion-proof distribution box, 4 explosion-proof lights, and 1 explosion-proof emergency light. 6.1 The outer shell of the main control distribution box is made of aluminum alloy material and coated with epoxy resin.6.2 Explosion-proof fluorescent lights are used for internal lighting, and an explosion-proof emergency light is installed at the exit.6.3 The internal temperature sensor, air conditioner, and combustible gas sensor all adopt explosion-proof designs.6.4 The internal circuit laying of the cabinet is set according to explosion-proof requirements. |

|

7 |

Chemical Leakage Recovery System |

The integrated leakage system inside the cabinet can accommodate 15% of the total volume. |

|

8 |

Fire - fighting and Extinguishing System |

There is 1 set of pipeline-type automatic fire extinguishing device inside the cabinet. When the temperature rises due to a fire, the dry powder agent in the fire extinguishing device will be ejected from the nozzle under the action of nitrogen to extinguish the fire. The fire extinguishing device features fast fire extinguishing speed and safe use. |

|

9 |

Personal Protective Equipment |

9.1 A human body static electricity discharge column is installed at the entrance of the cabinet and connected to the main body of the cabinet. It is used for the staff to touch before entering to discharge the static electricity carried on their bodies and prevent static electricity hazards.9.2 An independent lightning surge protector is installed at the main power supply access point to prevent static electricity hazards.9.3 The static electricity discharge system consists of three angle irons with dimensions of 2500505mm inserted directly into the ground to ensure that the static electricity of the cabinet is less than 4Ω. |

|

10 |

Video Surveillance System |

10.1 There is 1 explosion-proof video surveillance camera inside the cabinet, with ultra-high definition of 960P resolution and night infrared surveillance function.10.2 There is 1 ultra-high definition 960P peripheral surveillance camera installed outside.10.3 An RJ45 network port is reserved for docking with the school's total surveillance system.10.4 The video surveillance system has a storage and memory function, which can record surveillance data for more than one month and can be viewed at any time on mobile phones and computers. |

|

11 |

Remote Monitoring System |

11.1 There is one set of humidity indicating device, temperature sensing device, and combustible gas monitoring sensing device respectively inside the cabinet, with an LED on-site data display function, which are used for monitoring the internal environment of the cabinet.11.2 Each sensing device can monitor the interior of the cabinet in real time for 24 hours. When the indicators reach the set safety values, various handling measures and alarms will be intelligently executed through the control system.11.3 When the parameter indicators reach the set values, the monitoring system will send text message notifications to remind customers to pay attention. |

|

12 |

Emergency Eyewash and Shower |

12.1 The height of the shower is 2100mm±20mm, and the height of the eyewash is 1030mm±20mm.12.2 The eyewash and shower use a combined structure made of SU304 stainless steel, which can withstand a water pressure of >5kg/cm².12.3 It is installed on one side outside the cabinet door and can be reached within 5 seconds in case of an emergency. |

The outdoor shelf - type explosion - proof temporary storage cabinet warehouse is an ideal solution to the problem of storing dangerous goods in complex outdoor environments.

In terms of structural design, the main body of the warehouse adopts a sturdy steel structure frame, which can resist strong winds, heavy rain and other severe weather. The internal shelf - type explosion - proof temporary storage cabinets have a flexible shelf layout and strong load - bearing capacity. They can be adjusted individually according to the size, weight and category of the stored items, effectively improving space utilization. Whether it is small chemical reagent bottles or larger industrial gas cylinders, they can be stored in an orderly manner.

In terms of safety protection, the warehouse provides all - round guarantee. The cabinets are made of special steel with excellent explosion - proof performance, and are processed by special technology, which has excellent compression and impact resistance. The surface of the shelves has been treated with anti - static measures, and is equipped with a complete electrostatic grounding system, which can eliminate static electricity in time and prevent explosion hazards caused by static sparks. At the same time, the warehouse is equipped with an efficient explosion - proof ventilation system to keep the air circulating at all times, timely discharge the flammable and explosive gases that may be generated, and maintain a safe gas environment. In addition, the intelligent gas leakage monitoring and alarm device operates in real - time. Once an abnormality is detected, it immediately issues an alarm and starts emergency treatment measures, building a solid defense line for the safety of the warehouse.

In terms of application scenarios, its applicability is extremely wide. In the field operation bases of the petrochemical industry, it can be used to temporarily store various flammable and explosive chemical raw materials and oil products, providing safety guarantees for the continuity of production operations. At construction sites, it can store acetylene, oxygen cylinders and other items required for welding and cutting operations, ensuring the safety and order of the construction process. In the mining area, it can be used as a temporary storage point for blasting materials. With its reliable explosion - proof performance, it can reduce accident risks and meet the needs of different industries for the safe storage and efficient management of dangerous goods in outdoor environments.

Address

No. 158, Chaoyang Road, Donggang Town, Xishan District, Wuxi City, Jiangsu Province, China.

Tel