Cabinet Material: The cabinet is constructed entirely from steel plates. It is integrally formed through folding and welding of 1.2mm cold-rolled steel plates, with no visible weld seams on the surface of the cabinet. The surface is coated with epoxy resin through electrostatic spraying, making it both aesthetically pleasing and durable.

Weighing Management System: The weighing platform can automatically convert between the units of q and mI for reagents. It is equipped with a high-precision weighing system. The material of the weighing pan is acrylic, which has the advantages of being anti-static and corrosion-resistant.

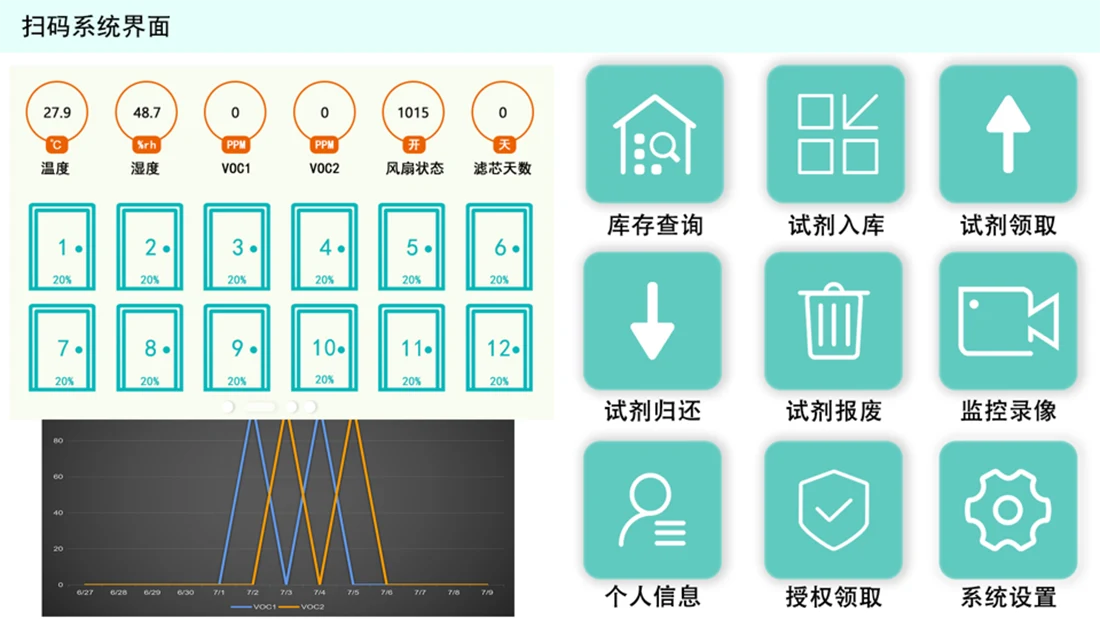

Scanning System: It has high-performance reading capabilities, enabling it to quickly and accurately read barcodes. Even when the labels are damaged or contaminated, it can still maintain a high recognition rate.

Data Management System: The integrated software system can record each weighing data in real time, automatically update the inventory information, support the tracking and tracing of chemicals, and can automatically generate reports.

Fingerprint Recognition System: It can accurately identify the fingerprint information of chemical administrators to ensure the safe use of chemicals.

Facial Recognition System: It can accurately identify the facial information of chemical administrators to ensure the safe use of chemicals.

Card Swiping System: Dual-card recognition is adopted to achieve dual-person management, ensuring the safe use of chemicals.

User Interface: It is equipped with a large 15.5-inch touchable screen, which provides clear operation instructions and displays the weighing results. At the same time, it supports permission management to ensure that only authorized personnel can operate the weighing and transfer of sensitive chemicals.

Permission Management System: It defines the scope of rights and responsibilities of laboratory personnel at different levels in the management of hazardous chemicals. Multiple levels of permissions are preset in the background, and it supports batch uploading and exporting of data in Excel format.

Label Printing System: It contains detailed information about the chemicals, such as name, weight, expiration date, etc.

|

Product Model |

Product Parameters |

|

GS-JST01 |

1.Smart Chemical Reagent Settlement Station with Scanning Function: Dimensions:H1320*W505*D585 Cabinet: It is constructed with all steel plates. The 1.2mm cold-rolled steel plates are formed into one piece through edge folding and welding. There are no weld seams on the surface, which is coated with epoxy resin through electrostatic spraying. Weighing System: It can automatically convert the units (q and mI) of reagents. With high precision, it is equipped with an acrylic weighing pan that is anti-static and corrosion-resistant. Scanning System: It has high performance, enabling it to read barcodes quickly and accurately. It also has a high recognition rate for damaged or contaminated labels. Data Management: It records weighing data in real time, automatically updates the inventory, supports the tracking and tracing of chemicals, and can automatically generate reports. Identity Recognition: It includes a fingerprint recognition system and a facial recognition system, which can accurately identify the information of administrators. The card swiping system adopts dual-card recognition for dual-person management. User Interface: It is equipped with a large 15.5-inch touch screen, which provides clear operation instructions and result displays. It also supports permission management. Permission Management: It defines the rights and responsibilities of personnel at different levels. There are multiple levels of permissions in the background, and it supports batch import and export of data in Excel format. Label Printing: It can print detailed information of chemicals, such as the name, weight, expiration date, etc. |

|

GS-JST02 |

2.Chemical Reagent Settlement Station with Intelligent RFID Recognition Function Cabinet: It has an all - steel structure, integrally formed by folding and welding 1.2mm cold - rolled steel plates. There are no weld seams on the surface, which is electrostatically sprayed with epoxy resin, making it both aesthetically pleasing and durable. Weighing System: Equipped with a high - precision weighing sensor, it can automatically convert the units (q and mI) of reagents. The weighing pan is made of acrylic, which is anti - static and corrosion - resistant. RFID Reading System: Special RFID tags are attached to each chemical reagent bottle or container, containing detailed information about the reagent, such as name, CAS number, RFID code, QR code information, expiration date, and weight. The reader can automatically identify this information through non - contact rapid reading, reducing the direct contact between operators and hazardous chemicals. Data Management: It can record weighing data in real - time, automatically update inventory information, support the tracking and tracing of chemicals, and automatically generate reports. Identity Recognition: It includes fingerprint and facial recognition systems to accurately identify the information of chemical administrators. The card - swiping system uses dual - card recognition for dual - person management to ensure the safe use of chemicals. User Interface: A 15.5 - inch large touch - screen provides clear operation instructions and displays weighing results. It also supports permission management, restricting the operation of sensitive chemicals to authorized personnel only. Permission Management: It defines the rights and responsibilities of laboratory personnel at different levels in the management of hazardous chemicals. Multiple levels of permissions are preset in the background, and it supports batch import and export of data in Excel format. Label Printing: It can customize the printing of label reagent information, including product name, CAS number, RFID code, QR code information, etc., and contains detailed information about chemicals such as name and weight. |

Our intelligent chemical settlement station integrates cutting - edge technologies and is truly a revolutionary product in the industry. It is equipped with an RFID intelligent recognition function, paired with a high - precision weighing sensor, which can accurately read reagent information and conduct precise weighing. The all - steel cabinet is integrally formed by folding and welding 1.2mm cold - rolled steel plates, and its surface is electrostatically sprayed with epoxy resin. This not only makes it sturdy and durable but also ensures safe usage. The advanced data management system can record weighing data in real - time, automatically update inventory information, and achieve efficient tracking and traceability of chemicals.

In the chemical production industry, this settlement station can help enterprises precisely control the use of raw materials, reduce costs, and improve production efficiency. In scientific research laboratories, its high - precision weighing and intelligent recognition functions can ensure the accuracy of experimental data and reduce human errors. Meanwhile, the strict identity recognition and permission management systems, such as fingerprint recognition, facial recognition, and the dual - card recognition system, guarantee the safety of chemical usage. It is widely applicable to various industry scenarios with strict requirements for chemical management.

Address

No. 158, Chaoyang Road, Donggang Town, Xishan District, Wuxi City, Jiangsu Province, China.

Tel