In the working environment, there are few cases where the safe storage of gas cylinders involved in production complies with regulations, and people know little about the hazards of random storage of gas cylinders. Most enterprises do not store gas cylinders in accordance with standards, posing great potential risks.

According to Article 45 of the "Regulations on the Safety Supervision of Gas Cylinders" issued by the State Bureau of Quality and Technical Supervision: Units storing filled gas cylinders should have a special warehouse for storing gas cylinders. The gas cylinder warehouse should meet the requirements of the "Code for Fire Protection Design of Buildings", and the number of stored gas cylinders should comply with relevant safety regulations. Take acetylene as an example:

At the site where acetylene cylinders are used, the storage of acetylene gas shall not exceed 30m³ (equivalent to 5 cylinders, referring to acetylene cylinders with a nominal volume of 40L). When the storage volume of acetylene gas exceeds 30m³, a separate storage room shall be partitioned with non - combustible materials, with one side being a fixed wall. When the storage volume of acetylene gas exceeds 240m³ (equivalent to 40 cylinders), a storage warehouse with a fire resistance rating of not less than Class II shall be constructed, and the fire - prevention distance from buildings shall not be less than 10m. Otherwise, it shall be separated by a fire wall.

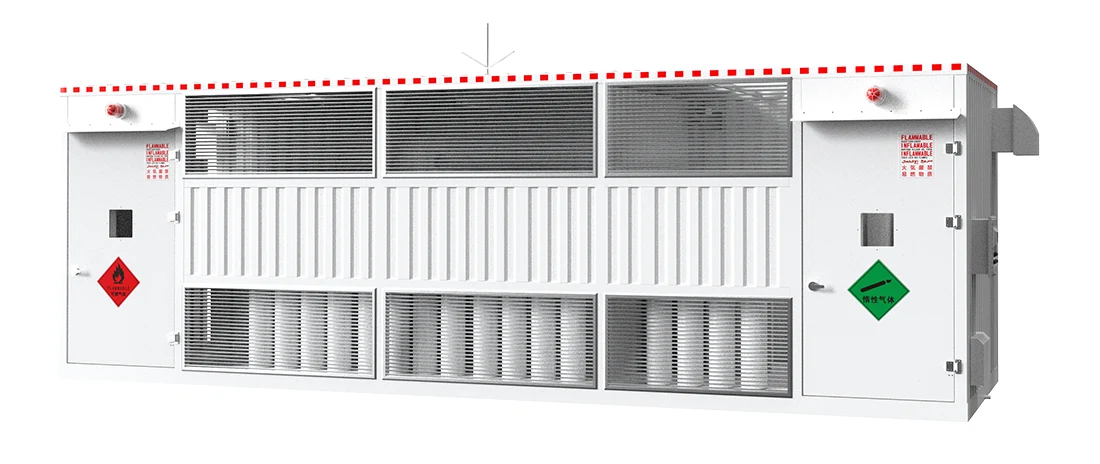

This product uses 2.0 galvanized high - quality corrugated sheet. As a widely used type of steel, it has good corrosion resistance, heat resistance, low - temperature strength, and mechanical properties. It has good hot - working properties such as stamping and bending, and there is no heat - treatment hardening phenomenon (non - magnetic, with a service temperature range of - 196℃ to 800℃). It is corrosion - resistant in the atmosphere. However, in an industrial atmosphere or a heavily polluted area, it needs to be cleaned in a timely manner to avoid corrosion. It is widely used in the manufacture of equipment and parts that require good comprehensive properties (corrosion resistance and formability). Generally, the upper limit of its service temperature is less than 650℃, and it has excellent anti - rust and corrosion - resistant properties as well as good inter - granular corrosion resistance. For oxidizing acids, experiments have shown that it has strong corrosion resistance in nitric acid with a concentration of ≤65% below the boiling point. It also has good corrosion - resistant capabilities against alkaline solutions and most organic and inorganic acids. The service life is 5 to 10 years (the specific lifespan is determined according to the storage environment).

|

Serial Number |

Structure Name |

Function, Parameter Description and Configuration |

|

1 |

Cabinet |

The cabinet frame is mainly made of 2.0mm Corten A

steel plates. The outer cabinet consists of a steel frame, vertically

corrugated side - panels and end - panels, and horizontally and vertically

corrugated top - panels, all of which are pressed from cold - rolled steel

plates. The entire exterior of the cabinet is sprayed with anti - rust paint,

the inner walls are coated with anti - corrosion paint, and the bottom is

sprayed with polytetrafluoroethylene. The whole cabinet has anti - corrosion

capabilities. |

|

2 |

Intelligent Control System |

2.1 The control system is equipped with a 7 - inch full

- color screen, which can display the status of various parameters in real -

time. |

|

3 |

Internal Storage System |

Internal

Storage System |

|

4 |

Ventilation and Exhaust System |

The ventilation and exhaust system consists of 4 ventilation

louvers and ventilation manifolds. |

|

5 |

Temperature Control System |

The temperature control system consists of a full -

inner - wall fire - proof and heat - insulating layer and 3 explosion - proof

air conditioners. |

|

6 |

Explosion - proof Power Supply System |

The explosion - proof power supply system consists of 1

explosion - proof distribution box, 3 explosion - proof lights, and 3

explosion - proof emergency lights. |

|

7 |

Fire - fighting and Extinguishing System |

7.1 Three sets of automatic fire - extinguishing devices are installed on the top inside the cabinet. When the fire temperature rises, the dry powder agent in the fire - extinguishing device is ejected from the nozzle under the action of nitrogen for fire - fighting. The fire - extinguishing device has the characteristics of fast fire - extinguishing speed and safe use. |

|

8 |

Electrostatic Protection Device |

8.1 A human body electrostatic release column is set at

the cabinet door, which is connected to the main body of the cabinet. Staff

can touch it before entering to discharge the static charge on their bodies

to prevent electrostatic hazards. |

|

9 |

Video Surveillance System |

9.1 One explosion - proof video surveillance camera is

installed inside each cabinet, with ultra - high - definition 960P resolution

and night - time infrared monitoring function. |

|

10 |

Remote Monitoring System |

10.1 One set each of a humidity indicator device, a

temperature sensing device, a combustible gas monitoring sensing device, and

a smoke detector are installed inside the cabinet, with LED on - site data

display function for monitoring the internal environment of the cabinet. |

|

11 |

Emergency Escape |

11.1 Emergency lighting lamps and safety exit indicators are installed above the cabinet door to facilitate personnel evacuation in an emergency. |

|

12 |

Emergency Eyewash and Shower |

12.1 The height of the shower is 2100mm ± 20mm, and the

height of the eyewash is 1030mm ± 20mm. |

|

Product Model |

Product Parameters |

|

GS-GCW |

Main Cabinet Dimensions (Length, Width, Height) H2800*W3000*L4000mm H2800*W3000*L6000mm H2800*W3000*L9000mm H2800*W3000*L12000mm It can be customized. (Overall double - layer box structure made of 2.0 corrugated sheets) Explosion - proof Air Conditioner Power: 1.5KW (including air - conditioner remote control). Ensures that the temperature inside the cabinet remains below the safe temperature during high - temperature summers. Louvers Length: 260mm; Height: 280mm Explosion - proof Fan Power: 0.18KW; Air volume: 2280m³/h for ventilation and air exchange Fan Cover + Filter Box Equipped with activated carbon filter cotton for filtering purposes Timer (Control for the explosion - proof fan switch) Display Screen Monitor for surveillance videos Explosion - proof Camera Used in conjunction with the display screen Safety Lock Impact - resistant door lock Gas Concentration Alarm System Capable of on - site and remote alarms Lightning Rod For lightning protection Round Explosion - proof Lamp Power: 40W; Explosion - proof lighting Emergency Equipment Cabinet Contains: Portable fire extinguishers, fire - resistant blankets, escape masks, etc. Dry - powder Fire Extinguishers For emergency backup Fire - resistant Blankets For emergency backup Escape Masks For emergency backup Suspended Fire Extinguishers Automatically activated when the temperature reaches 68°C, with a capacity of 4 kg for fire - fighting function Fixing Frame Stainless - steel chains suitable for 40L/50L gas cylinders Anti - slip Ramp Made of checkered plates for anti - slip and easy handling Rain Shelter For protecting against rain Explosion - proof Distribution Box The entire electrical box is made of high - quality steel plates and has excellent fire - prevention performance. The main power switch and fan controller are installed inside the box. Static Grounding Wire For anti - static purposes Power Cord + Tee + Round Tube Electrical appliance power cords, three - way elbow wires, cable - arranging round tubes, and hooks User Information Bag User manual, certificate of conformity, warranty card, equipment list, and various certifications Safety Signs For warning and reminding purposes |

The outdoor explosion - proof gas cylinder container warehouse is carefully designed to meet the safety storage needs of gas cylinders in various industries. Its layout is scientifically and rationally planned. Inside the warehouse, multiple storage areas are divided according to the types and properties of gas cylinders to ensure that different types of gas cylinders are stored separately and to avoid potential hazards caused by mutual reactions. The temporary storage cabinets are arranged orderly, and the passageways are spacious, facilitating the operation of forklifts and handlers, which greatly improves the efficiency of gas cylinder warehousing and outbound.

In terms of safety facilities, the warehouse is equipped with a full - range of explosion - proof devices. High - power explosion - proof exhaust fans are installed on the top to continuously ventilate and reduce the concentration of combustible gases. The surrounding walls are constructed with fire - proof and explosion - proof materials, which can effectively block external fire sources. Each temporary storage cabinet has multiple safety protections. The cabinet body is made of high - strength explosion - proof steel with excellent impact resistance; special gas cylinder fixing brackets are set inside to prevent gas cylinders from tipping and colliding. At the same time, an electrostatic grounding system and a gas leakage alarm device are equipped. Once an abnormality occurs, the alarm will be immediately activated and corresponding measures will be taken to comprehensively safeguard the safety of gas cylinder storage.

In terms of application scenarios, this warehouse is widely applicable to a variety of industries. In the industrial manufacturing field, it can store acetylene and oxygen cylinders commonly used in welding and cutting operations, ensuring the continuity of the production process. In the medical industry, it can temporarily store medical oxygen for first - aid and treatment, meeting the strict safety requirements of hospitals for gas supply. In scientific research institutions, it can store various special gas cylinders for experiments, facilitating the safe and orderly development of scientific research work and providing a solid and reliable solution for the gas storage needs of different industries.

Address

No. 158, Chaoyang Road, Donggang Town, Xishan District, Wuxi City, Jiangsu Province, China.

Tel